![]() A leading provider of PCB Assembly services in the USA.

A leading provider of PCB Assembly services in the USA.

When we say that we care, we actually mean it. When you partner with us, we do everything possible to make sure your assemblies are completed on-time to your specifications with the highest quality. We truly consider ourselves an extension of your company's team.

We are an International Traffic in Arms Regulations (ITAR) and SAM registered company. Contact us for our Cage Code.

We work with some of the premier Aerospace companies in the industry. We are an AS9100d registered company.

We have the expertise to assemble RoHs IPC Class 3 medical devices. Rigid, Flex, and Rigid-flex PCB assemblies.

Whether it be power or RF boards related to self-driving cars, we have the expertise to get the job done right the first time.

We can assemble critical control system printed circuit boards that will be exposed to challenging environments.

Radio Frequency (RF) PCB assembly has unique challenges that we can help with. Roger/FR4 hybrid PCB assemblies are routine for us.

To meet our customers' high-volume electronic manufacturing service demands, we've made a recent investment in an advanced production SMT line. This new SMT line features board destackers, end-of-the-line board catching, and cutting-edge equipment such as the DEK Horizon Neo iX, dual-gantry Yamaha YSM20-2 with automatic tray exchanger, and BTU oven.

The Zenith 2 AOI, unique in the industry, sets its inspection criteria according to IPC-610 standards for electronic assembly acceptability. Koh Young's quantitative True 3D measurement-based approach enables broader inspection coverage, including advanced tall component inspection. The Zenith 2 provides precise AOI measurements, accurately identifying various defects, such as missing solder, offset, polarity, upside down components, OCV/OCR issues, solder fillet problems, billboarding, lifted leads and bodies, tombstoning, bridging, and more.

This X-ray component counter ensures accurate counts that exceed 99.9% for most components, guaranteeing precision. Optimized for speed, Assure rapidly counts components, enabling us to process inventory quickly, while also reducing labor time and costs. It takes approximately 10 seconds to count a single reel and less than 15 seconds for four reels.

This selective solder machine's pot has dual nozzles, which allows us to quickly and precisely solder through-hole components of different sizes without changing nozzles. With both Leaded and Lead-Free solder pots and nozzles, we are ready for leaded or RoHs PCB assemblies.

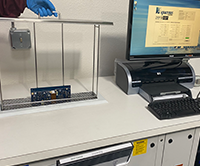

This machine helps us test boards for ion contamination during the PCB assembly process to make sure that the assemblies meet our customer's requirements.

The speed, precision, and flexibility of this machine allows us to manufacture LED printed circuit board assemblies up to 58 inches long. This Swiss army knife pick and place machine has been a great addition to our facility.

Titan Circuits — a division of Outroar LLC — specializes in high-mix, low to medium volume electronic manufacturing services in the USA. We operate on the principal that quality is built into all of our processes. From beginning to end, quality is in the forefront. We are committed to providing cost-effective, high-quality PCB assembly services with superior customer service.

Printed circuit board (PCB) assembly is the process of soldering electronic components onto bare boards. Electronic components installed on the bare board can be through-hole and/or surface mount (SMT). If the assembly has both, it is sometimes referred to as a high mix printed circuit board. PCB assembly is one segment of the electronic manufacturing process. Other segments can include cable/wire harness, mechanical/box builds, programming, and functional testing.

PCB fabrication is the process of manufacturing the bare board. The bare board is then used in the PCB assembly process. We offer both turnkey pcb assembly services and any combination of consigned kits. Turnkey pcb assembly is when we provide the PCB fabrication, components, and assembly labor. Customers can consign components and bare boards as long as the component overages follow our guidelines and the bare board panelization meets our requirements.

Please email or call us (888-913-9522) to learn more about our printed circuit board assembly services. We are here to help you with all of your electronic manufacturing needs.

work with us